ژر توضیحات

حالت: نوی

ټاکل شوې بریښنا: 7.5 کلو واټه

طول (L*W*H): 2100*3200*1600

وزن: 1000KG

سند: سی ای ISO

تضمین: 1 کال

د پلور وروسته خدمت چمتو شوی: انجینران په بهر کې د خدماتو ماشین ته شتون لري

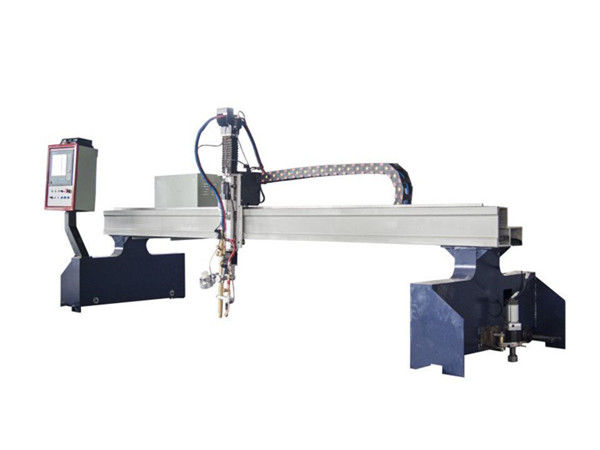

د محصول نوم: کوچني ګینټري cnc پینټوګراف فلزي پرې کولو ماشین / cnc پلازما کټر

رنګ: مطلوب

د کټ کولو مواد: د فلزي سټینلیس سټیل کاربن فولاد المونیم

غوښتنلیک: د فلزي شیټ پرې کول

سکرین: LCD

د کټولو سرعت: 0-8000 ملي متره / دقیقې

د قلمو ضخامت: 0-200 ملي میتر

د پلازما عرضه: Jiangsu Jiusheng

سافټویر: سټارکم

د CNC سیسټم: F2300B

اصلي برخې

1.Beam استعمال خطي لارښود.

2. بیم د بکس ډول جوړښت او ګینټري چوکاټ غوره کوي. د ویلډینګ وروسته ، د فشار فشار راحت درملنې په کارولو سره د پاتې فشار کمولو لپاره او دا د خرابیدو لامل نه کیږي.

3. میخانیکي لیږد سیسټم ټول دقیق بال بیرینګونه غوره کوي او د پروسې دقت ملي معیاري کچه 7 د ګیر او ریک دقیق میشینګ کوي.

4. د ډرایو سیسټم د چین-آلمان همکارۍ لخوا د سیارې کمولور غوره کوي. د دې د ننوتلو او محصول تېروتنه یوازې 16 آرک. په افقی او عمودی ګیر لیږد جوړښت کې د اتوماتیک جبران تشې وسیله ډیروي کوم چې کولی شي د لیږد جوړښت د CNC سیسټم لخوا ترتیب پلي کړي.

5. د اصلي ډرایو بیم: د اوږدوالي ریل کلیمپینګ وسیله د اتوماتیک اورینټیشن جوړښت غوره کوي ، نه د ځیرک څرخ کلیمپینګ وسیله. دا د اتومات لارښود جوړښت پسرلي ځواک باندې تکیه کوي او دا په دوه لارښود کې مستحکم حرکت کوي او سخت او نرمه پدیده نه ښکاري.

6. د سکرو او فولادو جوړښت ټولې برخې ټول تور یا کروم پلیټینګ پروسې کاروي.

تخنیکي پیرامیټر

نه | توکی | ارزښت | واحد |

1 | ټرانسورس لارښود فاصله | 3000 | ملی میتر |

2 | د کښت کولو مؤثره چوکۍ | 2500 | ملی میتر |

3 | اوږدوالی لارښود ریل اوږدوالی | 8000 | ملی میتر |

4 | د اغیزمن پرې کولو اوږدوالی | 6000 | ملی میتر |

5 | د پلازما قطع کولو ضخامت | د کاربن فولاد ≤6 دی | ملی میتر |

6 | مشعل پورته او ښکته لوړوالی | ≤150 | ملی میتر |

7 | د ریبلو سرعت | 50-3500 | ملي / منټ |

8 | د ډرایو سیسټم | سټپر موټر | |

9 | د ځړولو سافټویر | سټارکم |

برخی

1. ښه دقت، لوړ دقت. VSR د فشار سره معامله کولو لپاره.

2. د فولادو پلیټ ویلډیډ جوړښت، د تودوخې لوړ کول، د ماشین ژوند ډاډمن کول.

3. عمودی او افقی ډرایو.

4. کورني سټیپر ډرایو (د اختیاري لپاره وارد شوي ډرایو سیسټم).

5. د اتوماتیک پروګرام کولو سیسټم، کوم چې نمونه او اسانه کار کوي.

6. د CNC کنټرول.

7. د CAM nesting سافټویر.